Product Description

Welding Cable with EPR/NBR rubber jacket, according to IS 6830/84 equivalents to BS 6899 and DIN VDE 0282 part 6

- Conductor resistance

according to IS: 8130/84 equivalent to HD 383 cl. 6.

- Conductor resistance factor

at +20˚ C – see technical information

- Temperature range

flexing -25˚ C to +80˚ C

fixed installation -40˚ C to +80˚ C

- Admissible working temperature

at conductor +85˚

- Nominal voltage 100V

- Test voltage 1000V

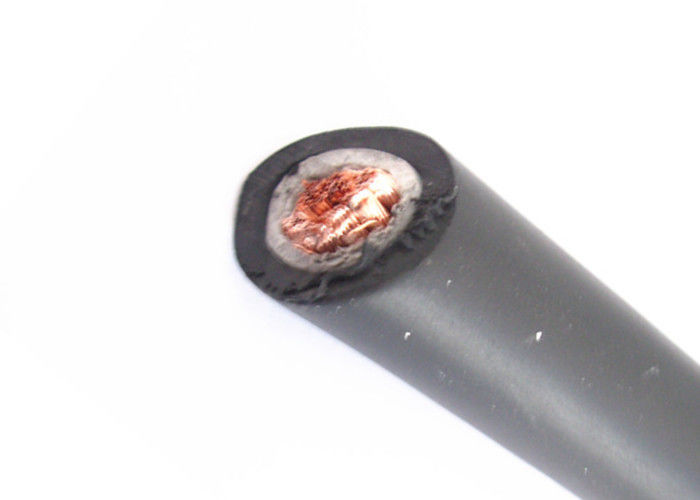

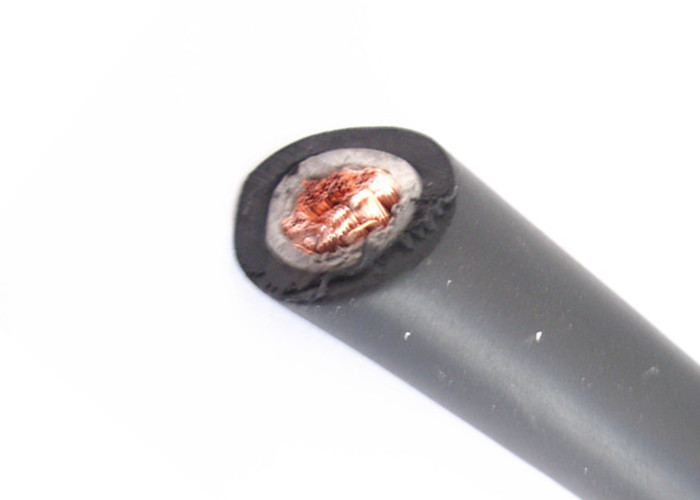

Cable structure :

- Plain copper conductors, extra fine stranded to IS 8130/84 equivalents to BS 6360, IEC 60228 & HD 383.

- tape used as separator over the conductor.

- EPR/NBR outer rubber jacket, as per type SE-3.

- Outer sheathing black

- With marking of brand name and cross section.

- Testing of cable carried out as per IS 9857/90 equivalents to BS 638 part 4.

- Heat, oil and fire retardant cable.

Application

- Rubber insulated flexible welding cable are used to connect Welding Machine & for better welding proficiency.

- Used in Automobile industries, Shipbuilding, Transport, Steel Plans, Railways, Refineries, Oil fields, Automatic Welding Robots, Construction, Coal Mines etc.

- The robust construction makes these cables resistance to both cold & heat as well as to flames.

- They are suitable for use in open spaces and in dry and damp conditions.

Welding Cable with standard flexibility, bending radius : approx. 15 x CableØ

Cross-Sec

(Sq.mm) |

Current Rating At a Max Duty Cycle |

No. of x Single

Wires WireØ

(mm) |

Radial thickness

of sheathing

(mm) |

Outer Diameter

min ~ max

(mm) |

Max Resistance

@ 20˚C

(ohm/km) |

AWG

No. |

Permanent

100%

(Amps) |

85%

(Amps) |

60%

(Amps) |

30%

(Amps) |

| 1x16 |

513 x 0.2 |

2.0 |

8.7 ~ 10.7 |

1.210 |

135 |

146 |

174 |

246 |

6 |

| 1x25 |

783 x 0.2 |

2.0 |

10.5 ~ 12.5 |

0.780 |

177 |

192 |

228 |

343 |

4 |

| 1x35 |

497 x 0.3 |

2.0 |

12.1 ~ 14.1 |

0.554 |

221 |

240 |

285 |

403 |

2 |

| 1x50 |

702 x 0.3 |

2.2 |

14.0 ~ 16.0 |

0.386 |

279 |

303 |

360 |

509 |

1 |

| 1x70 |

999 x 0.3 |

2.4 |

16.2 ~ 18.2 |

0.272 |

352 |

382 |

454 |

643 |

2/0 |

| 1x95 |

1302 x 0.3 |

2.6 |

18.9 ~ 20.9 |

0.206 |

424 |

460 |

547 |

774 |

3/0 |

| 1x120 |

1702 x 0.3 |

2.8 |

20.2 ~ 23.2 |

0.161 |

491 |

525 |

601 |

814 |

4/0 |

| 1x150 |

2121 x 0.3 |

3.0 |

22.4 ~ 26.4 |

0.129 |

568 |

614 |

708 |

921 |

300Kcmil |

Welding Cable with extreme high flexibility, bending radius : approx. 12 x CableØ :

Cross-Sec

(Sq.mm) |

No. of x Single

Wires WireØ

(mm) |

Radial thickness

of sheathing

(mm) |

Outer Diameter

min ~ max

(mm) |

Max

Resistance

@ 20˚C

(ohm/km) |

AWG

No. |

| 1x16 |

513 x 0.2 |

2.0 |

8.7 ~ 10.7 |

1.210 |

6 |

| 1x25 |

783 x 0.2 |

2.0 |

10.5 ~ 12.5 |

0.780 |

4 |

| 1x35 |

1120 x 0.2 |

2.0 |

12.1 ~ 14.1 |

0.554 |

2 |

| 1x50 |

1600 x 0.2 |

2.2 |

14.0 ~ 16.0 |

0.386 |

1 |

| 1x70 |

2240 x 0.2 |

2.4 |

16.2 ~ 18.2 |

0.272 |

2/0 |

| 1x95 |

3024 x 0.2 |

2.6 |

18.9 ~ 20.9 |

0.206 |

3/0 |

Safety Requirements

1. Coiled welding cable must always be spread out before using to avoid overheating in use.

2. Cables must not be spliced within 10 feet of the holder.

3. Welding cable must never be coiled or looped around the body of the worker.

4. Cables with damaged insulation must be replaced.

5. Welding cable must only be joined through the means of recommended connections.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!